PRODUCT CATEGORY

CONTACT US

AlMg2 / 5052 / 3.3525 Aluminum Ingot

Aluminum ingot is an important industrial raw material, which takes bauxite as the main raw material. After a series of complex refining processes, such as Bayer process, soda lime sintering process, etc., alumina is extracted from the ore, and then obtained by electrolytic alumina. The aluminum ingot has silver white metallic luster, soft texture, low density, excellent conductivity and thermal conductivity, and good ductility and corrosion resistance. Common aluminum ingots include high-purity aluminum ingots, aluminum ingots for remelting, etc., which are widely used in many fields such as construction, transportation, electronics, packaging, etc. for example, the construction industry is used to manufacture aluminum alloy doors and windows, the transportation industry is used to help the lightweight design of automobiles and aircraft, the electronics industry is the key material for circuit boards and shells, and the packaging industry is used to make aluminum foil, etc.

PRODUCT DETAILS

Parameter

Chemical Composition

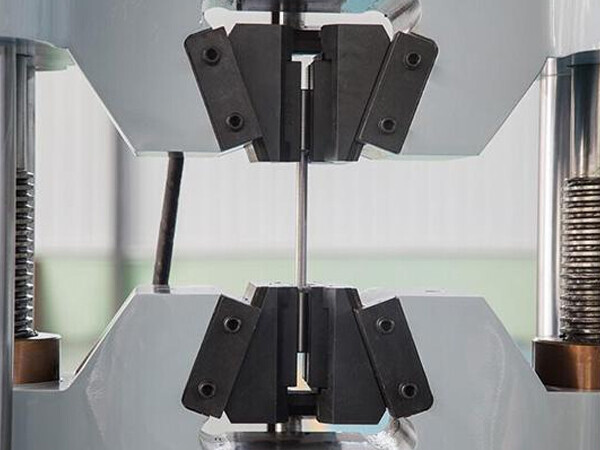

Mechanical Properties

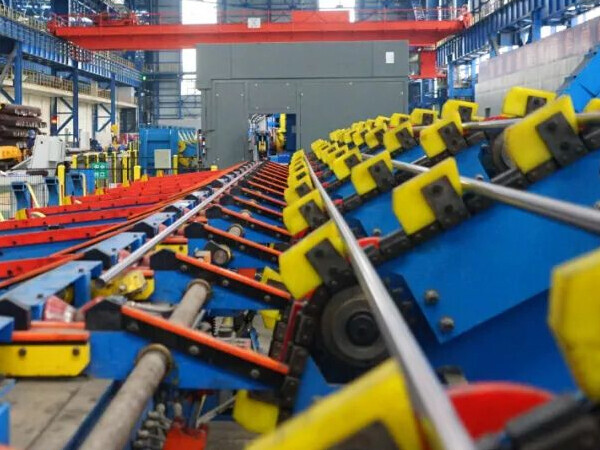

COMPANY STRENGTH

PACKAGING SHIPPING

ONLINE MESSAGE

SIMILAR RECOMMENDED

Get real-time quotes

Interested? Leave your contact details.